Nissie Bungbrakearti CODE 2121

Thursday 21 April 2016

Wednesday 6 April 2016

Tuesday 5 April 2016

Vertical Stability - Week 3

CARD TOWER

Construction Process:

In order to create a tower that had reasonable height and was structurally sound, we decided to waffle the cards. Interlocking them would stabilise the tower when enduring the "blow test". Consideration towards the tower possibly toppling over was combated by having a base and as the tower of cards grew taller, the structure grew thinner.

Observations:

During the blow test the tower was successful due to the wider base and thinner tower. The base allowed for wind forces to push the body of the structure and still stay standing.

Dimensions:

Height: 450mm

Base dimensions: 150mm x 150mm

Connection details: Waffling/ slits

Height/Width of Base:

450/150 = 3

Video Link

Construction Process:

In order to create a tower that had reasonable height and was structurally sound, we decided to waffle the cards. Interlocking them would stabilise the tower when enduring the "blow test". Consideration towards the tower possibly toppling over was combated by having a base and as the tower of cards grew taller, the structure grew thinner.

Observations:

During the blow test the tower was successful due to the wider base and thinner tower. The base allowed for wind forces to push the body of the structure and still stay standing.

Dimensions:

Height: 450mm

Base dimensions: 150mm x 150mm

Connection details: Waffling/ slits

Height/Width of Base:

450/150 = 3

Video Link

Thursday 17 March 2016

Horizontal Spans - Week 2

Observations and notes made from three bridges created in week 2

1. SATE STICKS

Construction

process:

Through

group brainstorming, we came up with an idea that mimicked weaving and

stacking. On the base layer five single sate sticks were laid out at equal

distances. On top of those, five more single sate sticks were laid across

evenly, but rotated 90 degrees to create a hatching pattern. The sate sticks

were then staked on further, using hot glue as a means of connection. The final

structure ended up approximately 2.5cm in height.

Observations:

With

only using the force of our hands pushing down on to the structure, it seemed

already quite strong. Once all the trays of paper were placed on top, two

people stood on top of it. The structure did not break after the paper weight

or the two human loads.

Weight

of structure:

67g

Weight

at breaking point/load collapse:

Approximately

157kg

Weight

of supported load/weight of structure:

157000.00g

/ 67.00g = 2343.28g

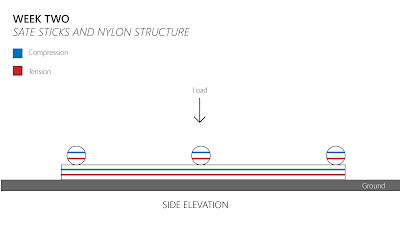

2. SATE STICKS AND NYLON

Construction

process:

Without

the aid of hot glue as a way to connect the sate sticks together, nylon and

rubber bands were used. These created pin joints in the structure which would

make it unstable if forces were to be placed on it upright. However since the

load would be vertical and the structure flat, the pin joints were not so much

of a concern. Nine sate sticks were grouped together to create more strength

and to reach the height of approximately 2cm.

Observations:

Similar

to the Sate Stick Bridge, the bridge by itself already seemed structurally

sound. This was confirmed when paper weight was loaded on to the tray and a

human load was able to bounce/jump up and down on the bridge without it falling

into itself or breaking.

Weight

of structure:

75g

Weight

at breaking point:

Approximately

90kg

Weight

of supported load/weight of structure:

90000.00g

/ 75.00g = 1200.00g

Construction

process:

Similar

to the paper bridge in week one, this bridge would follow the same accordion

like folds to create strength and have more surface area to the structure.

Since the bridge only had to be a minimum of 2cm high, the original 5cm high

construction paper was folded in half to make a resulting 2.5cm high bridge,

and also to create more density and stability in the bridge as a whole

Observations:

Once all

the paper weights were placed on top of the structure, three people were able

to stand on top of it before it gave way on the corner of the bridge. This

could be due to a lack of density and strength in that area of the structure,

or simply the person standing on that corner was heavier than the rest causing

it to collapse.

Weight

of structure:

51g

Weight

at breaking point:

Approximately 197.5kg

Weight

of supported load/weight of structure:

197500.00g

/ 51.00g = 3872.55g

Youtube Link

Thursday 10 March 2016

Horizontal Support - Week 1

Observations and Notes from the three bridges created in week 1

1. SATE STICK STRUCTURE

2. MONOFILAMENT ANCHOR BRIDGE

3. PURELY PAPER

YouTube Video Link

1. SATE STICK STRUCTURE

Construction

process:

The first brainstorm included using

triangular frames that would create a stable structure through compressive

forces. We also

wanted to build height in to the bridge as just a flat structure would not

support as much weight, and would collapse inward faster. The final bridge was constructed

by hot gluing three lots of sate sticks together to create a stronger frame.

The joints were also hot glued together. After final assembly it was

discovered that one side of the bridge was assembled upside down. The final

bridge measured up to be approximately 10cm in height.

Observations:

Once the tray was laid on top it was

obvious that structure was too narrow at the top,

not supporting the tray itself. The structure on one side was assembled the

wrong way so the forces didn't apply as we thought they would.

On one side the triangular support compressed to hold up the tray on one side, however

on the other there was very little support due to the triangle frame being

upside down.

Weight

of structure:

Approximately

65g

Weight

at breaking point:

It held about 6 kg before sliding off,

but not damaging the bridge itself.

Weight

of supported load/weight of structure:

6000.00g

/ 65.00g = 92.30g2. MONOFILAMENT ANCHOR BRIDGE

Construction

Process:

The original idea was to create

somewhat of a suspension bridge, however we discovered turning the main

structure upside down would create in itself an anchor. The monofilament

creates compressive forces on each side of the thick sate stick border, pushing

the central joint up instead of down.

Eight sate sticks were held together

with rubber bands to create a strong border and column for the monofilament to

span off. A triangular

structure was formed on top, bridging between the two side anchors to form a

base for the tray to sit on.

Observations:

Anchors were created on both sides of

the structure through tensile forces acting through the monofilament. This

forced the joint of the sate sticks to stay together and not break inwards. The bridge failed when a joint holding a bunch of Sate Sticks together broke and so the whole system collapsed with it.

Weight

of structure:

Approximately

120g

Weight

at breaking point:

The structure held about 12kg of weight before a human load was used to

exert further force (as we ran out of paper weight). A “considerable amount of force” was required

before one of the side joints gave way {approximately 30kg).

Weight

of supported load/weight of structure:

42000.00g

/ 120.00g = 350.00g

3. PURELY PAPER

Construction

Process:

In order to create a structure out of purely paper that could support

weight, the structure needed to be dense to create a decent strength to hold up

when compressed. An accordion like fold was made so that

the paper would be able to stand up by itself without the aid of any other

material. The height was made at the minimum

weight of 5cm so that it would be less weak.

Observations:

I believe the density of the accordion like fold is what made this

structure surprisingly successful. Another factor is the height of the paper.

The lower it is the more stable it is and likely to hold up a weight.

Weight

of Structure:

Approximately

50g

Weight

at breaking point:

The structure held up approximately 6 kg of weight before giving way. It seems as though

after one accordion piece collapsed, the rest became unstable.

Weight

of supported load/weight of structure:

60.00g /

50.00g = 1.20g

YouTube Video Link

Subscribe to:

Posts (Atom)